HO P3 Clinchfield 4-6-6-4 Challenger Steam Loco #670/Blk w/C

The Union Pacific

Challengers were a type of simple articulated 4-6-6-4 steam locomotive

built by American Locomotive Company for the Union Pacific. 105 of

these locomotives were built between 1936 and 1943. The Challengers

were about 122 ft (37 m) long and weighed 284,800 kg. Primarily in

freight service, they operated over most of the Union Pacific system. A

few were assigned to passenger trains operating through mountain

territory to California and Oregon. The locomotives were built

specifically for UP and much of the experience gained later went into

the design of the famous Big Boy.

The name

Challenger was given to steam locomotives with a 4-6-6-4 wheel

arrangement. This means that they have four wheels in the leading pilot

truck, which helps guide the locomotive into curves, two sets of six

driving wheels, and finally four trailing wheels, which support the

rear of the engine and its massive firebox. Each set of six driving

wheels is driven by two steam cylinders. In essence, the result is two

engines under one boiler. The Union Pacific Railroad sponsored

development of this type to meet the need for higher speeds in

main-line service. Historically, articulated locomotives had been

limited to slow speeds by factors inherent in their design. The

technical breakthroughs achieved with the Challenger enabled the

carrier to develop the Big Boy with the same speed expectations. Speeds

in excess of 60 M.P.H., while unheard-of on other railroads using

articulated steam locomotives, became commonplace on the Union Pacific.

Industry-Leading Features:

Product Information:

- NEW Paragon3 Sound &

Operation System FEATURING ROLLING THUNDERTM with Authentic Sounds

and Prototypical Operation in both DC and DCC environments - Synchronized PUFFING

SMOKE with Chuff Sound - Separate whistle smoke

- Variable Puffing Smoke

Intensity and timing - Integral DCC Decoder

with Back EMF for Industry Best Slow Speed Operation in DC and DCC - Precision Drive

Mechanism engineered for continuous heavy load towing and smooth slow

speed operation - Powerful High Torque

Motor with Fly Wheel - Premium Caliber Painting

with Authentic Paint Schemes - Prototypical Light

Operation with Golden White LED Headlight, Rear Light - Lighted number boards

- Lighted front marker

lights - Lighted rear marker

lights (red to the back and green to the sides) - Lighted cab light (with

auto shut off)

- Die Cast Body with Heavy

Die Cast chassis for Maximum Tractive Effort - Die Cast Tender

- Front coupler: option of

closed pilot door, working metal coupler, plastic dummy coupler - Rear coupler: working

metal coupler - Separately Applied

Handrails, Ladders, Whistle, and Brass Bell - Operating Cab Roof Vents

- Will Operate on Code 83

and 100 rail - Recommended Minimum

Radius: 18 inches - Traction tire equipped

Industry-Leading SOUND

Features:

- Operates in DC & DCC (use

DCMaster for DC Sound) - Record & Play Operation

– Records and plays back sounds and movements once or repeatedly for

automatic operation - 16-bit Sample Rate for

exceptional high frequency sound clarity - Playback Whistle for

multiple whistle lengths and patterns - Choice of 3 selectable Whistles

- Alternate Whistle / Horn

where applicable for locomotive with air horn and steam whistle – both

the main whistle and alternate can be easily played - Adjustable bell ringing interval

for faster or slower bell - Numerous user-mappable

functions with available keys - Johnson Bar or Power Reverse Sound

at Direction Change - Passenger Station Ambient Sounds –

Controlled with Function Key - Freight Yard related radio chatter

– Controlled with Function Key - Lumber Yard Ambient Sounds –

Controlled with Function Key - Farm related radio chatter –

Controlled with Function Key - Crew Radio Communications –

Controlled with Function Key - Maintenance Yard related radio chatter

– Controlled with Function Key - Demo Mode for display and

demonstrations - Grade Crossing

Signal – Controlled with Function Key - Simple Programming with

Integral DCC Decoder - Automatic Forward / Reverse Signal –

When activated, stopping triggers and stop whistle toot. When

moving forward from a stopped position, toots twice. When

moving in reverse, toots three times. - Chuff sound

intensity varies with load - Individually adjustable sound volumes

for most effects

**Specifications on this

page subject to change.

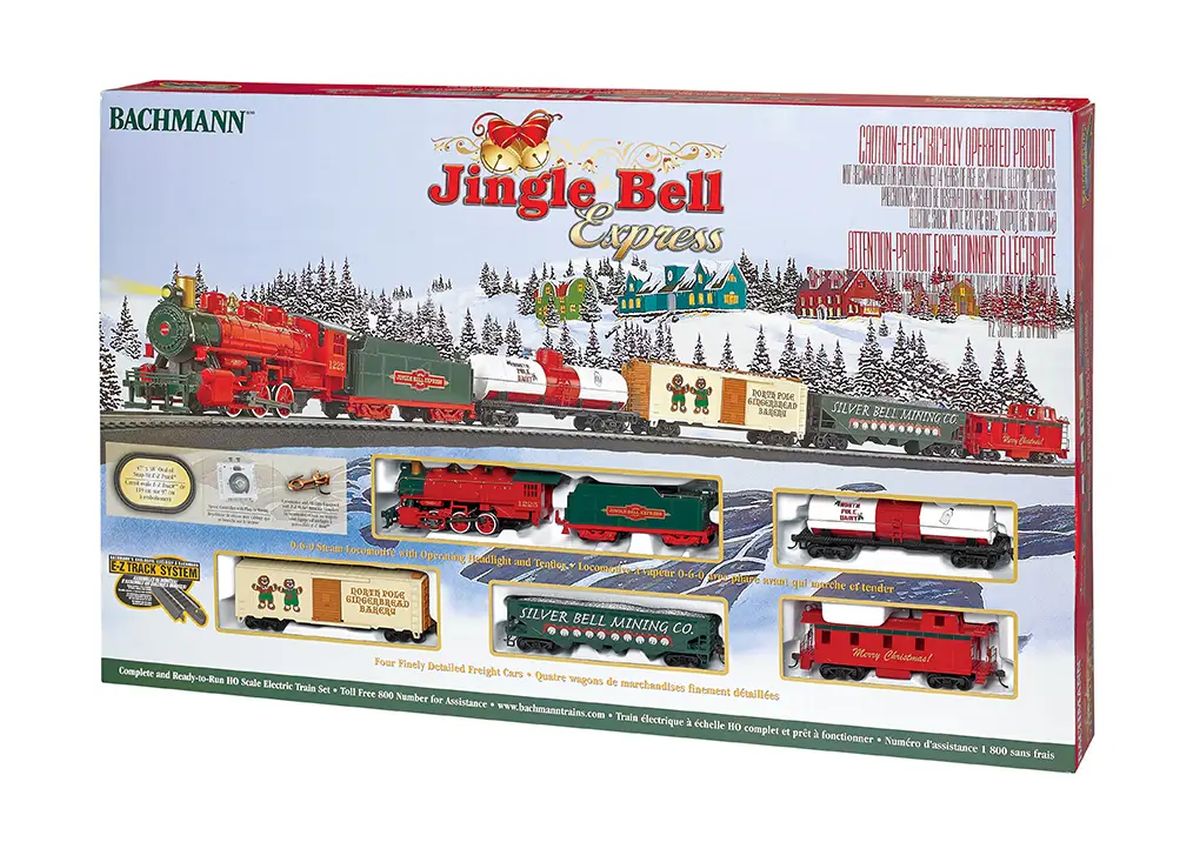

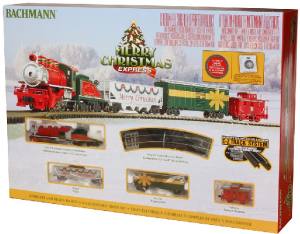

Featured Products

O Tank Car Christmas Cheer

O Tank Car Christmas Candy

McLaren F1 MCL38 #4 Senna Monaco 2024

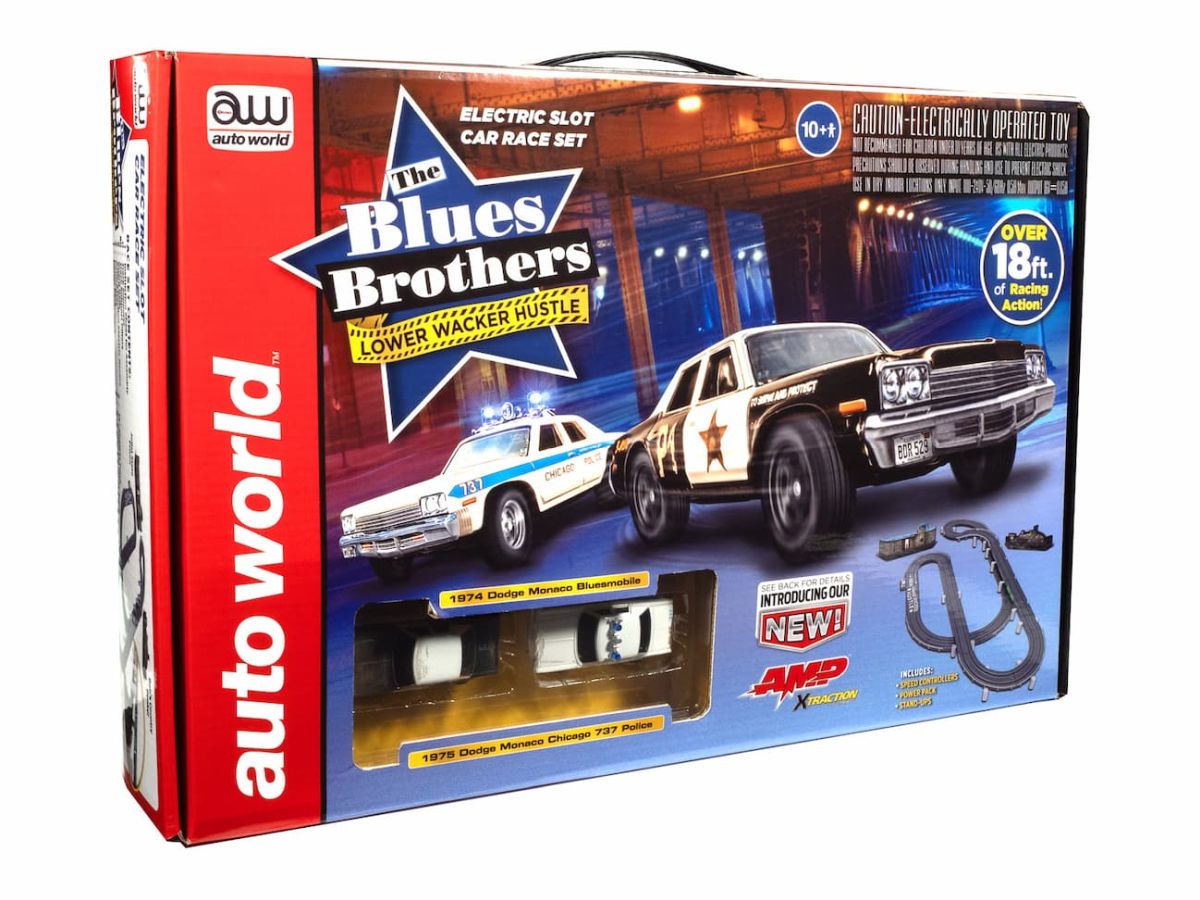

TARIFF 18′ Blues Brothers Lower Wacker Hustle Slot Race Set

Wash Away Paint Remover

Buffalo Snow Flurries Extra Fine

70 Shelby Gt-500 Skill 4

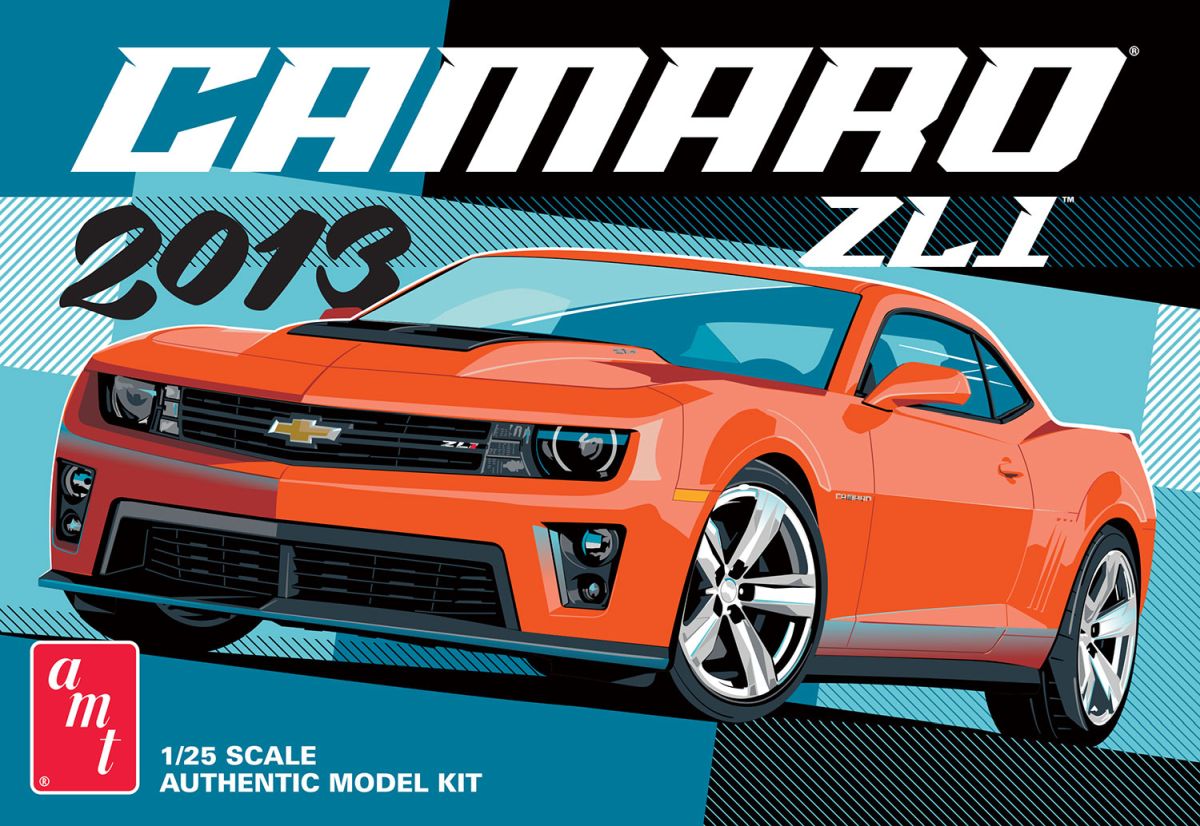

TARIFF 2013 Chevy Camaro ZL1 Skill 2

TARIFF 1969 Hurst Oldsmobile Cutlass Skill 2

N Merry Christmas Steam Freight Set/0-6-0